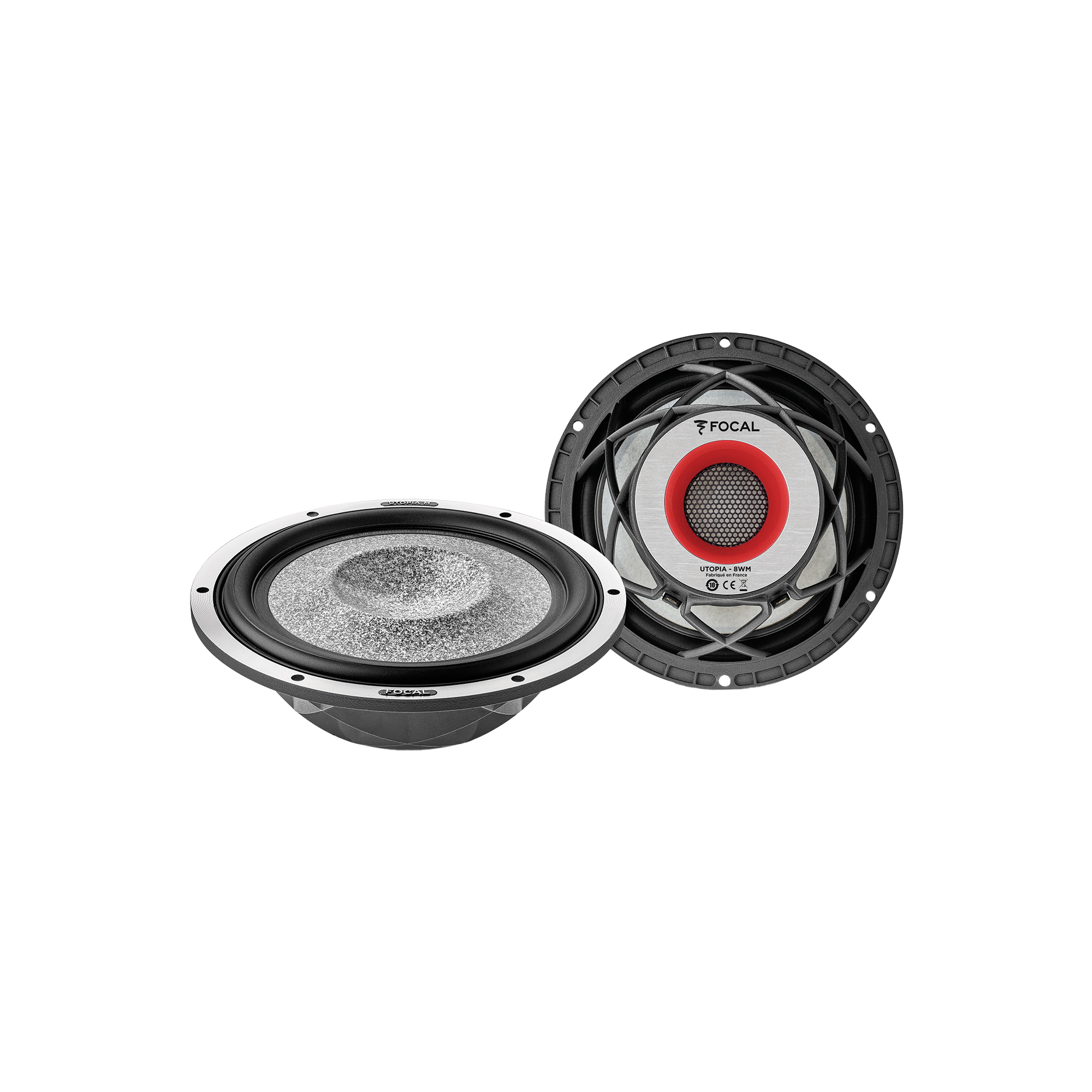

The "W" composite sandwich cone allows perfect optimization of the frequency response curve, right from the cone design stage, thanks to total control of three key parameters: lightness, rigidity and damping.

GLASS FIBRE STRUCTURE

The abbreviation "W" stands for Glass/Glass, as two or more sheets of glass are affixed to either side of the structural foam core. Rigidity is provided by the sandwich structure of the glass fibre fabrics. The glass used is a fine weave of long fibres.

LIGHTNESS AND HOMOGENEITY

This choice offers significantly lower mass and thickness than aramid fibre or Kevlar® fabrics, which generate coloration in the midrange. It is also important to note that the molecular bond between resin and glass is far superior to that obtained with aramid fibres. As a result, the cone's structure is more homogeneous and its behaviour in flex far superior.

OPTIMIZED ACOUSTIC PERFORMANCE

These unique characteristics of lightness and rigidity enable us to control the speed of signal transmission within the material. Modulating the thickness of the structural foam core enables precise control of the damping of the "W" composite sandwich cone. By varying the number of glass sheets and the thickness of the central foam, the membrane's behavior is optimized according to the frequency range to be reproduced.

When listened to, the "W" composite sandwich cone delivers total sonic transparency, very low distortion (20 times stiffer than Kevlar® or aramid fibre), and excellent phase response.

Focal products using this technology

Discover other Focal technologies

REMOTE AMPLIFIER IN CURRENT MODE

"M" profile Béryllium Tweeter

Infinite Horn Loading

JOIN THE COMMUNITY

Get a sneak preview of the latest audio innovations and new products from Focal and Naim by subscribing to our exclusive newsletters. Be among the first to benefit from privileged information delivered straight to your inbox.

Newsletter

New products and limited editions

Invitations to exclusive events

Benefit from special offers